Which Weapon Could be the Army’s New Rifle & Light Machine Gun?

July 13, 2020

NEXT GENERATION SQUAD WEAPONS (NGSW)

September 23, 2020It has been 11 months since the US Army awarded three OTA contracts as part of its Next Generation Squad Weapon program. Despite the uncertainty around the ongoing Coronavirus pandemic, the program remains on track and set to begin its next major phase. TFB had the pleasure of speaking with Lt. Col. Jason Bohannon, Product Manager – Next Generation Weapons, and Matthew Walker, Capabilities Developer, Soldier Lethality Cross Functional Team at U.S. Army Futures Command, to discuss the program, the weapons and the challenges ahead.

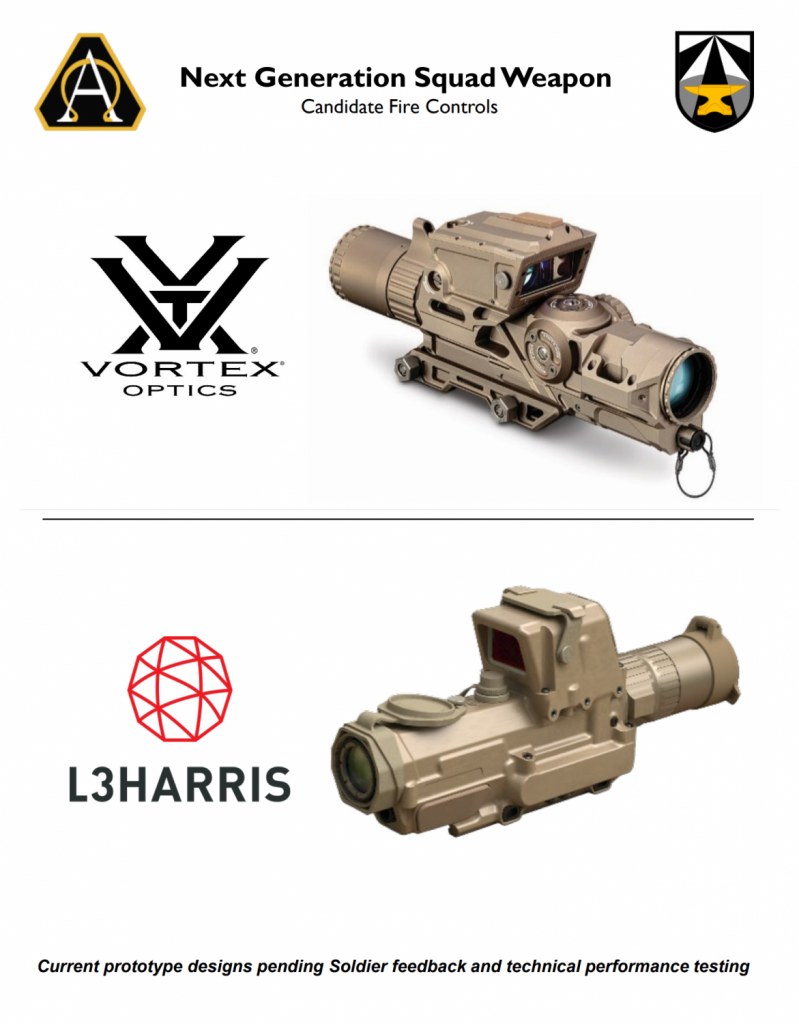

NGSW is certainly one of the most ambitious small arms programs the U.S. Army has ever embarked on, aiming to select not only a brand new rifle and automatic rifle, but also advanced new ammunition, which has the potential to kick-start a revolution and the next phase of small arms design. Weapons from General Dynamics, SIG Sauer and Textron Systems are being evaluated along with advanced fire control units from Vortex Optics and L3Harris.

At the beginning of our interview, Lt. Col. Bohannon confirmed that the technical testing of the NGSW prototypes is already underway. The tests began in the second week of June, at Aberdeen Proving Grounds. Lt. Col. Bohannon said the technical evaluations will run through to August and encompass all the classic tests, including environmental tests for temperature, dust, water immersion, as well as drop tests, sound profile testing, accuracy, round dispersion, cook-off and endurance tests.

(US Army)

In addition to the important technical testing, the first phase of Soldier Touch Points is about to begin. Matt Walker, whose office led the formulation of the Soldier Touch Points and decided on the cross-section of Soldiers who would be involved in the test program, explained which troops will be involved in the tests:

“The feedback will obviously be from expert Infantrymen. The target audience for these capabilities [of the NGSW] are what the Army has defined as the Close Combat Force. This consists of line Infantry, scouts, engineers, front line medics and forward observers from the Artillery. This represents about 10% of the Army, whose task it is to close with the enemy and destroy.”

Mr. Walker said NGSW can be seen as a very targeted capability, a specific tool for a specific role “kind of like mechanic in the motor pool gets certain tools.”

TFB: So expanding on that, can you comment on the types of units those involved are drawn from?

Walker: “Those involved are a broad, diverse group, with guys drawn from the line divisions, Special Operations Command and the Marines. The guys who we’re looking for to provide feedback are all senior but don’t get me wrong, there is an inclusion of younger guys … who definitely have input to make since training is such an important aspect of how well a person does with these new capabilities. Take the fire control unit; It benefits a sub-standard shooter and also benefits an expert marksman. We can see analytically that the fire control unit improves both. We’re not trying to replace training, obviously, but it’s a sliding scale, the more trained you are the better you can make use of the capabilities of the NGSW …”

TFB: As the program goes forward, will both weapon systems be selected from one manufacturer, or is there potential to take an NGSW-R from one and an NGSW-AR from another, providing ammunition commonality was feasible? Is there flexibility for this kind of outcome built into the procurement plan?

Bohannon: “Right now, the plan is to choose the rifle and automatic rifle from the same vendor. We’re fully funded, and the requirements are pretty stable to achieve that. However, I would say we maintain some flexibility. At the end of the day, if it was decided that there was an alternative solution, we might approve one gun and continue on a separate path for another. Soo there is flexibility for an off-ramp, but right now everyone is planning for one vendor.”

TFB: Is there similar flexibility to use one manufacturer’s ammunition plan with another manufacturer’s weapon design?

Bohannon: “Ultimately, that comes down to the selection criteria. We have to weigh the benefits and weaknesses of the rifle, the automatic rifle, the manufacturing capability and special license agreements.”

TFB: In terms of the NGSW Fire Control Unit, when are the prototypes from the recently awarded contracts for NGSW-FCUs set to join the Soldier Touch Points process?

Bohannon: “The very first thing we did once the award was official was give (vendors) access to high-quality shooters. So we took both of those vendors [Vortex & L3Harris] to Fort Benning, Georgia, and Soldiers from the Army Marksmanship Unit, 75th Rangers and conventional forces gave feedback on things like reticle patterns, menus, button placement, etc. We provide the range, the marksmen and the safe conditions for feedback and the vendors can spend the week collecting feedback that we expect they will include in their design process. That’s something that traditionally isn’t done, but it’s worked well for us. We did the same thing at the beginning of the competition last year; As soon as we down-selected, we took the guns down to Fort Bragg. It was very beneficial.”

TFB: For the FCU, were there only two slots planned for the down-selection?

Bohannon: “We planned to select up to two. We could have gone with just one, but we had two really solid submissions. We really hoped to see a competitive environment… and I think we have that in both the fire control unit and the weapons competition.”

TFB: Can you comment on the environmental aspects of the polymer-cased ammunition used by 2 of the 3 ammunition entries? Are the potential environmental impacts of this something that the Army has considered? Has the potential pollutant effect of polymer been factored into the program?

Bohannon: “You’re the first person to ask me about that! The Army over time has always sought to minimize environmental impacts where possible. We took lead out of the M855A1, so there is always a desire to reduce negative environmental impacts. At the same time, you’ve got to balance that with soldier load and capitalizing on emergent technologies. So for the last two years, offices around the Army have been exploring alternatives to the traditional brass case, and we’ve seen some really innovative efforts.”

Matt Walker: “The desire to eliminate toxic products from being used by Soldiers is something that in the last two decades the Army have been making big strides. That hasn’t always been the case. There’s probably less of an impact from polymers than there is from injecting all those metals into the environment. We’re trying now to remove residual lead from primers, too.”

TFB: In turn, how do you mitigate complex and harsh environments impacting ammunition with not traditional components like polymer?

Walker: “Plastic and polymer is relatively inert and doesn’t really interact with the environment.”

Bohannon: “We’ll be doing the same testing that we would on brass cases, so we’ll take them to extreme hots and colds. We’re really trying to stress these systems to the point of failure, so we know where their left and right limits are, and ultimately the Soldier Lethality Cross Functional Team and Maneuver Center of Excellence at Fort Benning will be able to determine if that performance is acceptable for an Infantryman that has to operate in extreme environments.”

TFB: Moving away from the environmental considerations, NGSW-AR has been positioned as a replacement for the M249 SAW, but with 6.8mm GP potentially outperforming M80A1 and XM1158 in terms of velocity and penetration. Will it also replace the 7.62x51mm M240?

Walker: “There’s an awful lot of discussion about that. When we talk about the range and energy at range and the ability to make use of that energy against a target, 6.8 GP is definitely showing itself to be pretty capable of being competitive against the 240 machine gun. There’s work to be done. This is obviously the first entry into this next growth area of small arms. As we take this step with these weapons into the next growth area, because remember some of those systems – the M16, M4, M27 – have had fifty years of evolutionary improvement, The NGSW are just the first step, so we don’t even know what they’ll look like in 10-15 years from now. So maybe we’ll replace the 240, or maybe there’s another program down the line that’s a more robust approach, perhaps a little heavier, a little bit longer barrel, maybe weighs a few pounds more… and maybe we would be able to go to a common cartridge for the entire platoon, which obviously, logistically would be beneficial. Actually, we’ve had this discussion with a couple of corps commanders who asked the exact same question: Are we looking to replace something in the weapons squad? Are we looking at increased capability? That remains to be seen.”

(Photos by Sgt. Cody W. Ewing/U.S. Army)

TFB: Is the performance specification for the 6.8mm GP-based rounds still in flux? Can we get confirmation of projectile weight and minimum expected velocity?

Bohannon “We’re still not giving out any data with regard to velocity or effects of the system. Like all of our rounds, they started out at Lake City Army Ammunition Plant and throughout time, they continue to get better and better in terms of tolerances and variances. So it’s going to outperform anything on the battlefield today, and it’s going to continue to evolve, become more and more accurate the more rounds that Lake City builds. To date, they’ve manufactured almost a million projectiles.”

TFB: What is the expected role of the M4 after NGSW weapons begin to be fielded? Will it fill an M1 Carbine-esque echelon role or gradually be phased out entirely?

Walker: “Vietnam was the last time we really had the separation of weapon types between the Close Combat Forces. While most engagements are somewhere between 150 and 250 meters, there’s really not a lot of long range shots. But there is a need, in our view, for the close combat Infantryman to have a weapon that affords him the capability specifically against near-peer threats to still reach out and touch somebody at range. The M4 will remain in the force in Brigade Combat Teams. The NGSW-AR will replace the M249s in the [Squad Automatic Weapon] role, but the 249s in the LMG role – those will stay in light machine gun roles where they’re equipped with a longer barrel, etc.”

TFB: Integrated powered rails are a desire for the successful weapons. What sorts of accessories is the Army seeking to power with the rail, and what is an acceptable weight to lethality increase ratio?

Bohannon: “That’s a good question; we debated with that. We looked at what we need to do to just add the rail itself – the Picatinny smart rail; you’re not really adding weight. It’s when you start running a conduit or any kind of batteries. But the ability for that rail to either pass power or data through is an attempt to create a kind of open architecture on the weapon system. Once that open architecture exists, a market space exists, so like laying fibre optics in your house before you had Fios. At the end of the day, this gun has to do a few things: it has to kill; it does not have to pass data and power to be successful. But that is something we can continue working. We really wanted the vendors to think through how they would do it at the earliest stages of development.”

TFB: Has the Covid-19 pandemic had any impact on the program? Have there been any major delays to the evaluation process? Can we expect to see the awarding of final contracts delayed?

Bohannon: “It’s been a tough couple of months that have forced the team to re-plan and stay in a reactive state. There was no pause, we had to adapt. We did see some sub-suppliers that had issues and we had to delay the technical testing by 30 days. Then we found ways to restructure deliveries downstream and restructure testing in order to sustain a six month timeline before the record test. Overall, we’ve had no slip of the program delivery date but it’s an aggressive schedule. We’ve been able to accomplish this through an adaptive team of professionals that talk regularly with the vendors, sometimes a few times a week. We treat it as a partnership.”

TFB: What are the immediate program priorities at the moment?

Bohannon: “We’re going to be in this development for the next year. Prototype test #2 is scheduled to start next year in the spring of ’21; that’s the record test. Everything we’re doing this summer is the diagnostic test. The vendors will receive the raw data from that, to preposition them to be as competitive as possible next year.”

TFB: Finally, could you elaborate on what the biggest challenges the NGSW concept faces before it becomes a mature weapon system?

Walker: “All of the weapons I’ve fired are capable, and all of them, in their own way, are ingenious or novel. Also, there’s an awful lot of attributes that have been added ergonomically that only a person that uses a weapon as the tool of their trade would appreciate – things being where they’re supposed to be, so you can operate them quickly. Over time, some weapons have not afforded that. We’re now seeing that Soldiers system concept – designing things as a system, not trying to integrate features once they finally arrive with the Soldier. To make industry bring to the table a consolidated approach for their system. You’ll remember with the Modular Handgun System a couple of years ago … we did not define the calibre, we just said ‘It has to be able to do this …’, and we were willing to adapt in the event vendors brought forward something better. It’s just a different way over the last six to eight years, of doing acquisition. There have been a lot of bruises and scrapes and bumps over time, but some of the biggest challenges are just going to be gaining consensus and making an informed decision.”

Bohannon: “When I boil my job down, it really comes down to managing risk and there’s risk associated with all programs. I look at money, requirements and authority. When we started this program a couple of years ago, there were a lot of unfunded requirements, and Army was still trying to decide if it was going to accelerate the rifle and treat this as a systems approach with the fire control unit. Now we’re fully funded. I’m pretty fortunate, there are very few PMs in the world that have a good requirement and have a good relationship with the requirement’s developer… Matt and I have worked for years together, and we’ve debated small arms developments dating back to the 1950s, the Special Purpose Infantry Weapon and all the subsequent developmental efforts.

“There are mitigations that we applied to this program that at a strategy level didn’t exist for really big efforts. For instance, the Future Combat Weapon or OICW, these were large scale developmental programs that really shot for the moon. Ours was banded by five years and five years and had heavy vendor input because we believed if it couldn’t be developed in five years, it would be too hard to maintain momentum and support. We completed a series of market research days with industry. We had classified market research days, we hosted vendors at Fort Benning and Picatinny Arsenal to discuss some really hard challenges, they were difficult conversations for us to have. Jumping forward to today, we have a very healthy competition going, so I believe that the Army has learned from the issues of the past and pivoted to this new way of doing acquisition. We are using middle-tier acquisition authority, which is not typical, we’re not using a traditional DoD requirement documents. Like all programs, when you’re doing something hard, you’re going to have some road bumps along the way but this method should give the Army flexibility and I think ultimately this is the way we should be doing business.”

The Next Generation Squad Weapon program is one of the U.S. Army’s top modernization priorities, and we will continue to follow its progress over the next 12 months as the testing continues and a vendor is selected. NGSW could herald some major shifts in small arms development, and we’re grateful to Lt. Col. Bohannon and Mr. Walker for taking the time to speak with us and give us some insight into the program.